Ningbo Rilson Sealing Material Co., Ltd.

Ningbo Rilson Sealing Material Co., Ltd. was founded in 2007, is a professional

Spiral Wound Gaskets manufacturer and

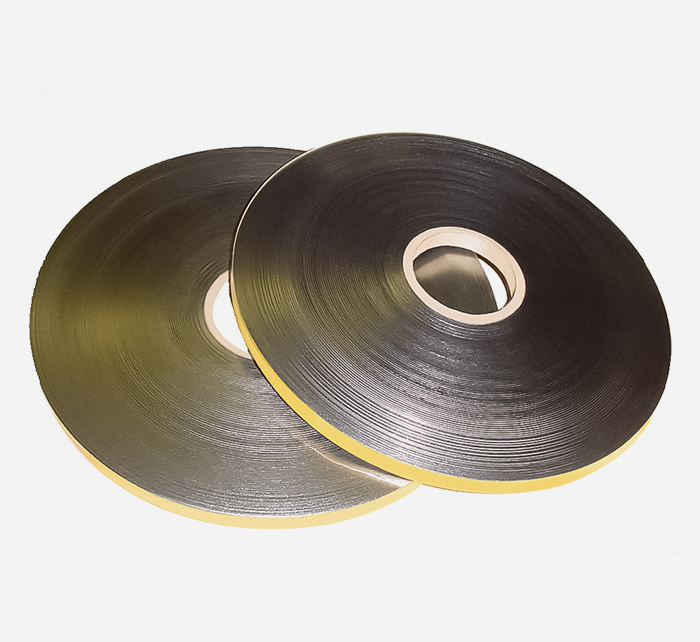

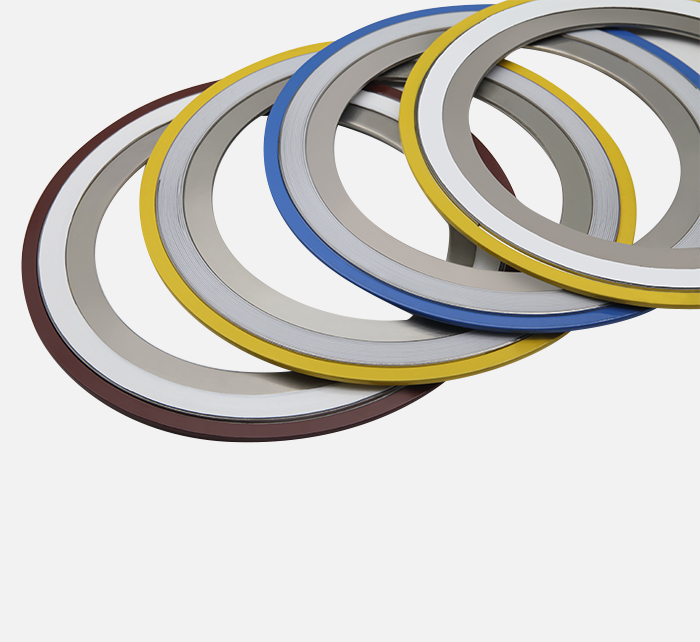

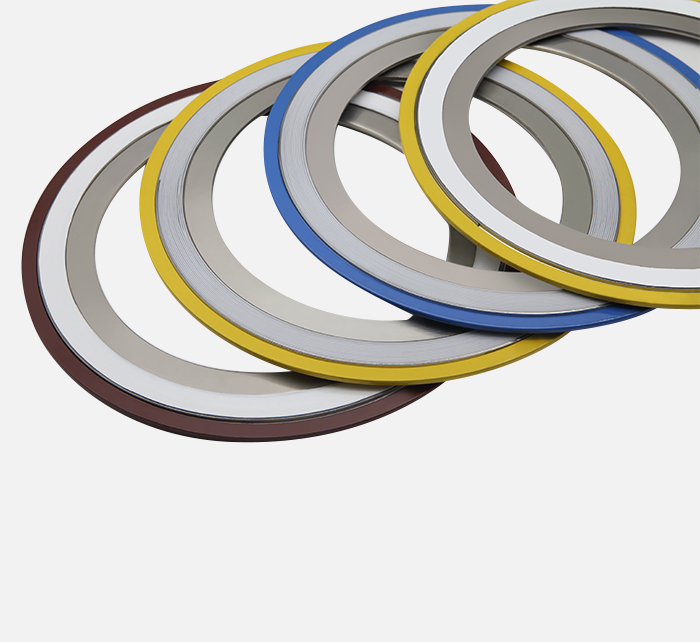

Spiral Wound Gaskets supplier and located in Ningbo, Zhejiang Province. The manufacturing facility spans across 20,000 square meters and is dedicated to ensuring the secure and dependable operation of fluid sealing systems, offering clients the appropriate sealing technology solutions. We operate numerous production lines for sealing products, specializing in the design and manufacture of sealing gaskets and other sealing materials for the petroleum, chemical, power, shipbuilding, and machinery manufacturing sectors. Our primary products consist of spiral wound gaskets, ring joint gaskets, kammprofile gaskets, corrugated metal gaskets, insulation kit gaskets, and Non-asbestos gaskets, among others.

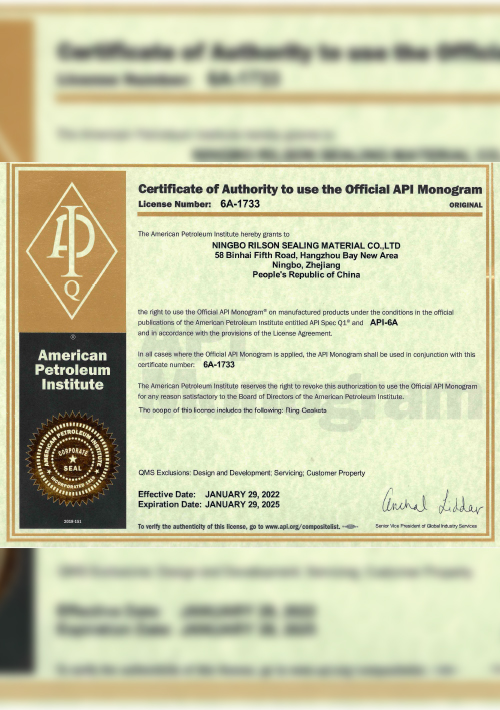

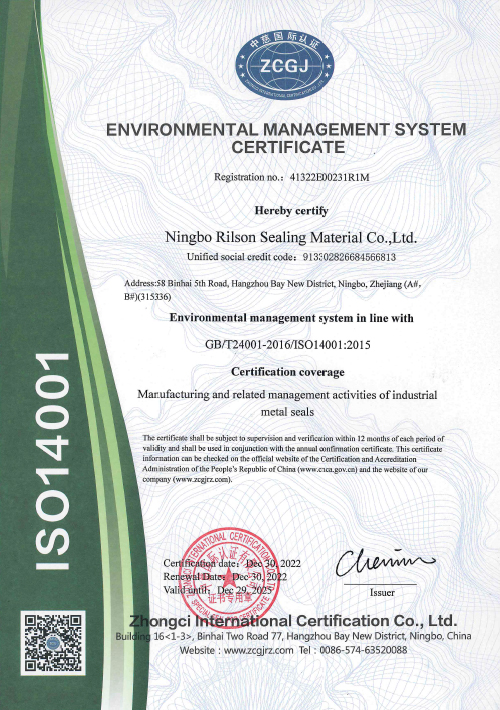

Our clientele hails from various parts of the globe, and through our extensive experience in the industry, we have earned the trust and recognition of our customers. Presently, we have obtained certifications from several prominent companies. Additionally, we have successfully achieved ISO9001:2015 quality management system certification, as well as the API 6A certificate, among others.

As a professional

Spiral Wound Gaskets factory, The company is dedicated to delivering value to customers, promoting health and happiness among workers, and producing positive social effects. We uphold the core principles of integrity, precision, innovation, and mutual success. With the aspiration of becoming the preferred brand in industrial gaskets, we are committed to establishing ourselves as a top-tier player in the fluid sealing industry and working towards the objective of ensuring mutual satisfaction among customers and employees.

English

English русский

русский 中文简体

中文简体 Spiral Wound Gaskes t with PTFE filler

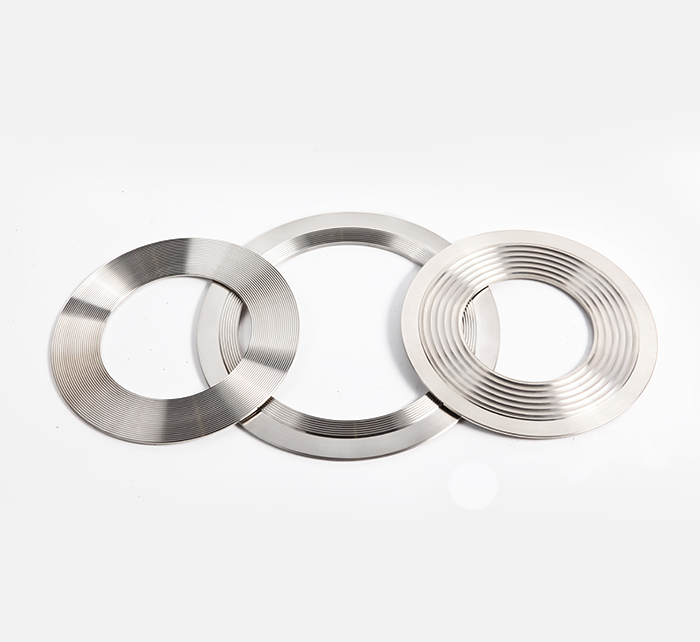

Spiral Wound Gaskes t with PTFE filler Spiral Wound Gasket with Kammprofile inner ring

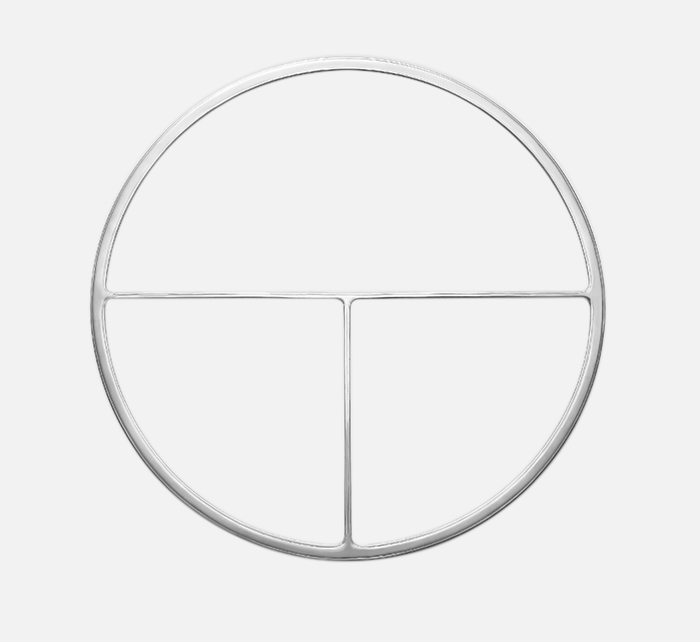

Spiral Wound Gasket with Kammprofile inner ring Spiral wound gasket with inner and outer ring

Spiral wound gasket with inner and outer ring Spiral wound gasket with inner and outer ring

Spiral wound gasket with inner and outer ring Spiral wound gasket without inner and outer ring

Spiral wound gasket without inner and outer ring